Team

A team of experts with profound knowledge, extensive experience and practice in international companies

project management of new product development

Professional approach to project management in accordance with the international Advanced Product Quality Planning (APQP) system

CERTIFICATION

Certificate of conformity with requirements of ISO:9001 quality management system

ABOUT COMPANY

SmithCraft Solutions Ltd (SCS Ltd) was established in 2018 as part of the general reorganization of AMO ZIL subsidiaries. As a successor of one of the subsidiaries, the company provided engineering and metal machining services to such customers as AMO ZIL, PJSC GAZ, Renault-Nissan-AvtoVAZ Group supplier.

In 2020, due to the reorganization of AMO ZIL production assets and the decision of the Moscow City Government to sell land plots for civil construction purposes, SCS had to seek diversification of its' activities.

Since 2022 SCS Ltd develops competencies in the field of development and organization of production of products made with the use of various technologies of metal and plastic processing, demanded by Russian consumers. In order to organize serial production of products, the company selects potential production partners of the People's Republic of China to organize contract manufacturing. Compliance of product quality with the required specification is ensured through independent audit of the Quality Management System (QMS) of the production partner and organization of product quality control at each stage of the production process.

Services

Manufacturing and components supply

Manufacturing and supply of metal and plastic components on a turnkey basis according to your Technical Assignment or Design Documentation

Engineering

Development of design documentation according to the customer's technical task

Product Performance Evaluation

Controllability, convenience in maintenance and operations

Verification and CORRECTION of the CUSTOMER'S design documentation

Selection of the optimal production technology in terms of balancing quality and cost of manufacturing the product based on the concept and technical specification.

Quality Control

Quality control and verification of finished products, measurements and laboratory testing

Computer simulations

Efficient load simulations in modern software packages to optimize performance and improve the reliability of your nodes

OUTSOURCING OF SERIAL PRODUCTION

Given recommended technology, search and selection of an outsourcing production facility (incl. China).

Development of the process flow documentation and production standards in cooperation with the selected technological partner.

Support of serial deliveries

Quality control of serial products, analysis of deviations using the “8D” method, launching the PDCA cycle, including identification of root causes of quality deviations, planning of corrective actions and preventive measures, control of implementation and efficiency of their application and effectiveness of their application

PROJECT MANAGEMENT FOR THE DEVELOPMENT OF NEW PRODUCTS

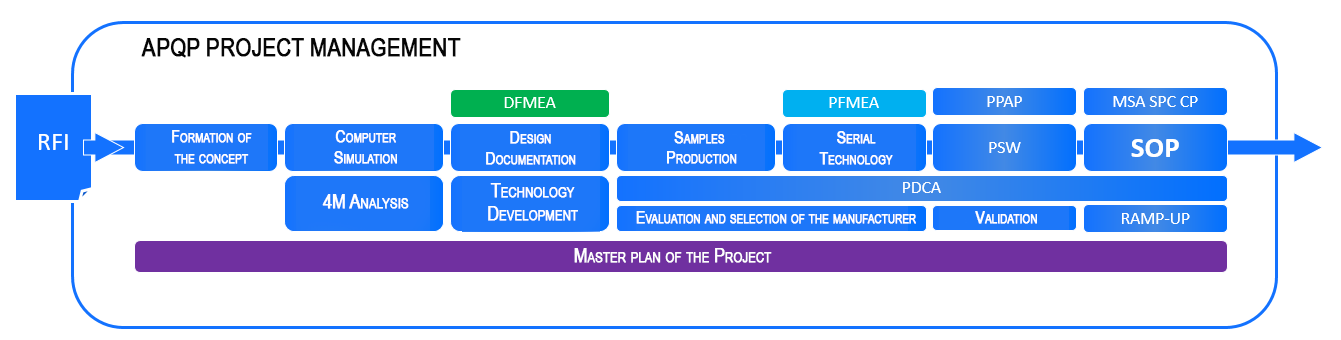

Project management according to the international APQP system from the RFI/RFQ stage to the beginning of serial product deliveries (SOP).

PRODUCTION LOCALIZATION

Study of opportunities and feasibility of partial or full localization of production.

PROJECT EXAMPLES

Differential gear

Precision forging, mechanical, chemical and heat treatment

DIFFERENTIAL SATELLITE

Precision forging, mechanical, chemical and heat treatment

Synchronizer hub

Powder metallurgy, mechanical and chemical heat treatment

SYNCHRONIZER CLIPS

Progressive steel stamping, plastic molding, subassembly

We are open to collaboration

PRINCIPLES OF PROJECT MANAGEMENT

The project management system pursued by the SCS team is based on the APQP system exploited by the international OEMs, including application of the failure risk analysis methodology (FMEA), 4M analysis, the Plan Do Check Action (PDCA) cycle, the Measurement systems analysis (MSA) method, the Statistical process control (SPC) method, along with the project administration process through composition of a project team, its work regulations and the system of client-supplier relationships protect Start of serial production (SOP) date from the risk of delay.

Standardized on the basis of the supplier assessment and development system (ASES), our own supplier selection system for semi or complete outsourcing of production allows us to ensure the predictable quality of the final product and consistent supply to the customer’s assembly line and develop countermeasures based on 8D non-conformities analysis.

The knowledge and experience of the experts involved in the project guarantee successful implementation of the project.

Our Team

Maxim Kondratyev

Founder, Strategy, Sales

More than 25 years of managerial work in Russian and international industrial holdings, including 10 years as General Director of Tier 1 OEM supplier “Alpha Automotive Technologies”.

Experience in leading the process of QMS implementation, including APQP project management system

Plant construction area 32 000 m2

Alexander Kapirusov

Director, Logistics, Purchases

Over 20 years of experience in procurement management, in major Russian mining holdings, including Evraz, Novatek, Russian Coal.

Participation in the OEM Tier 2 supplier QMS implementation project.

Certified Auditor ISO 9001:2015, ISO 19011:2018

Nikita Nefyodov

Project management, Development of design documentation

More than 6 years of experience in automotive project management in Tier 1 OEM supplier organizations such as “Magna Cosma International Rus”, “Alpha Automotive Technologies”.

Total experience in the automotive industry for over 8 years.

Dmitry Shappo

Technical expertise, project support

More than 14 years of experience in managing production and project teams of Tier 1 (VW, Renault) and Tier 2 (Magna Automotive Rus, Faurecia) OEM suppliers

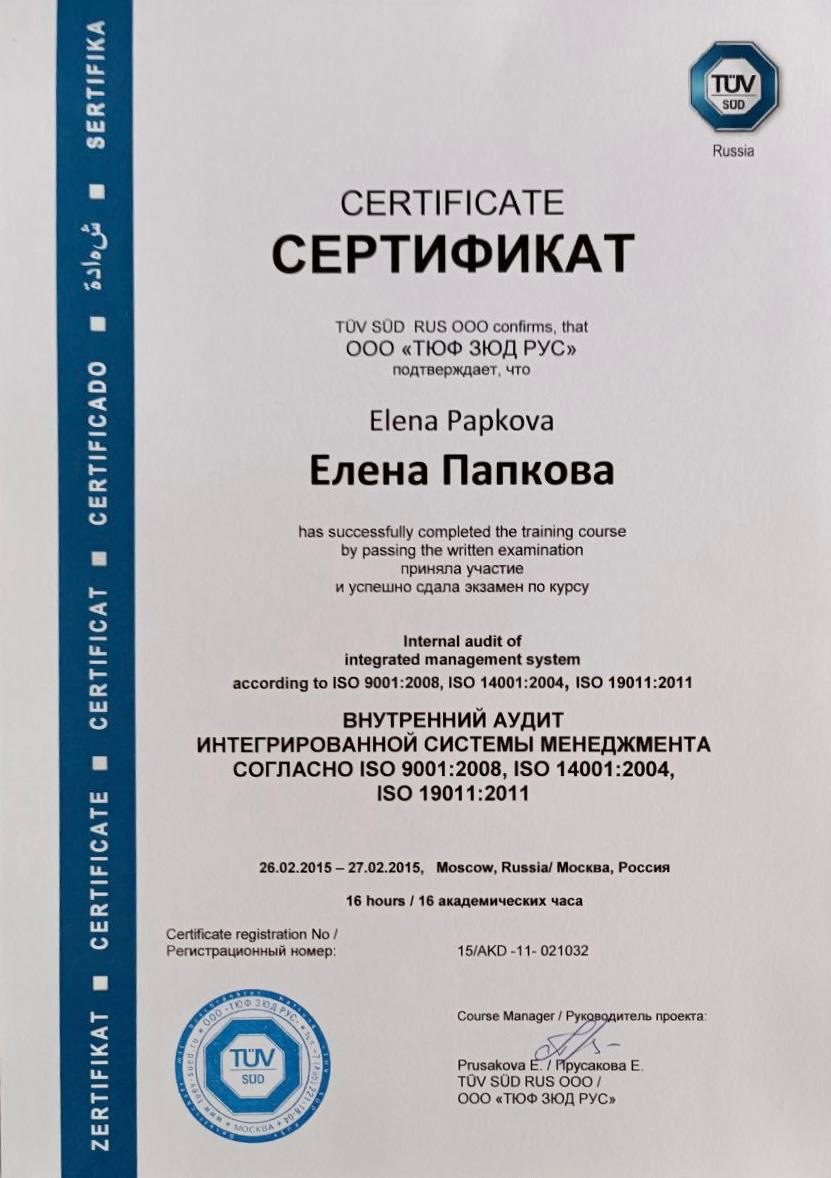

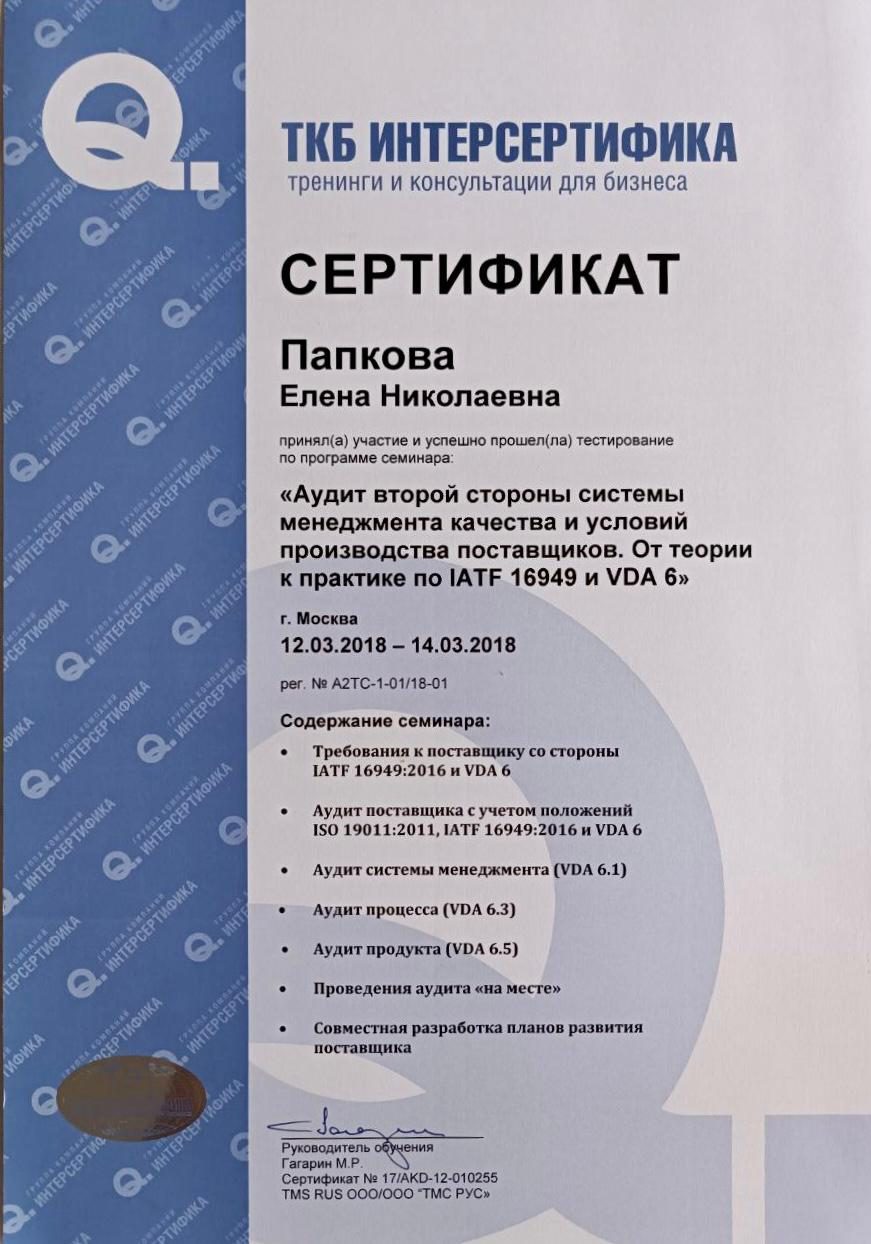

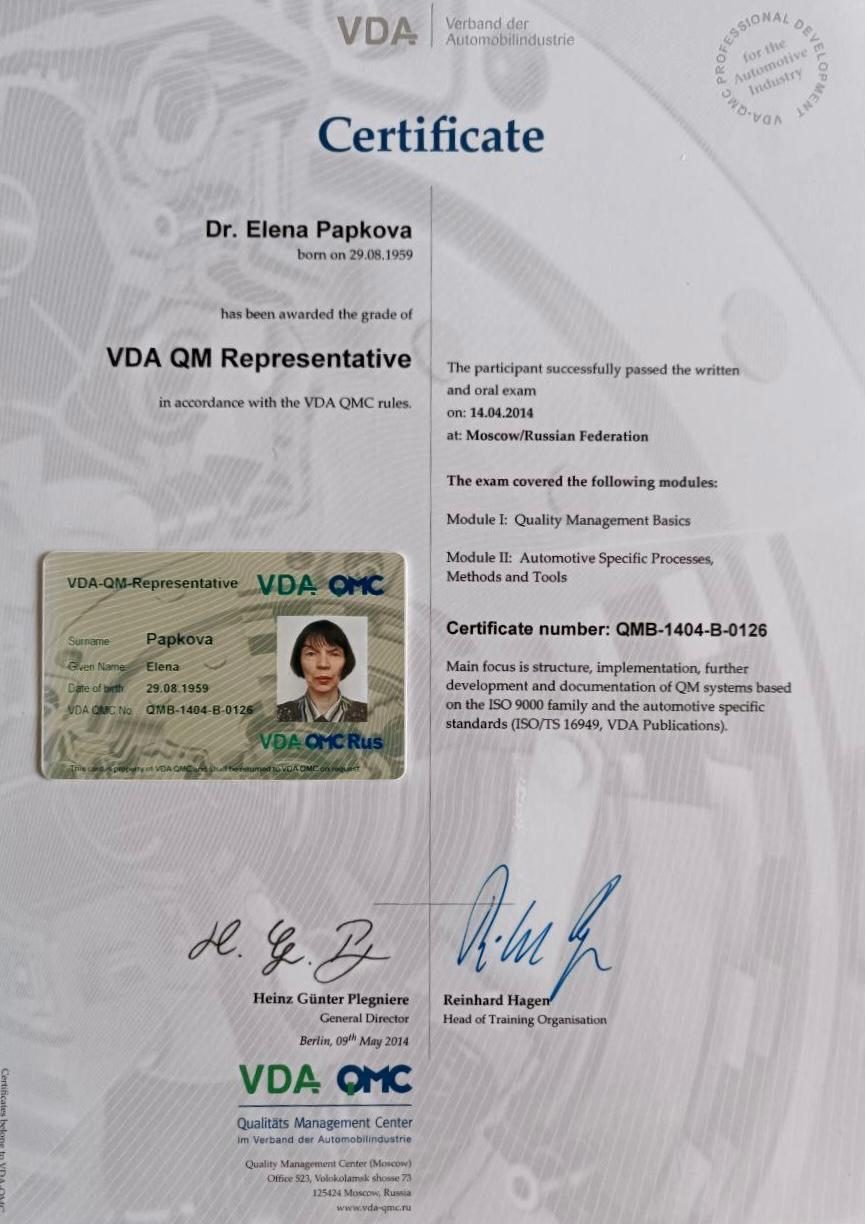

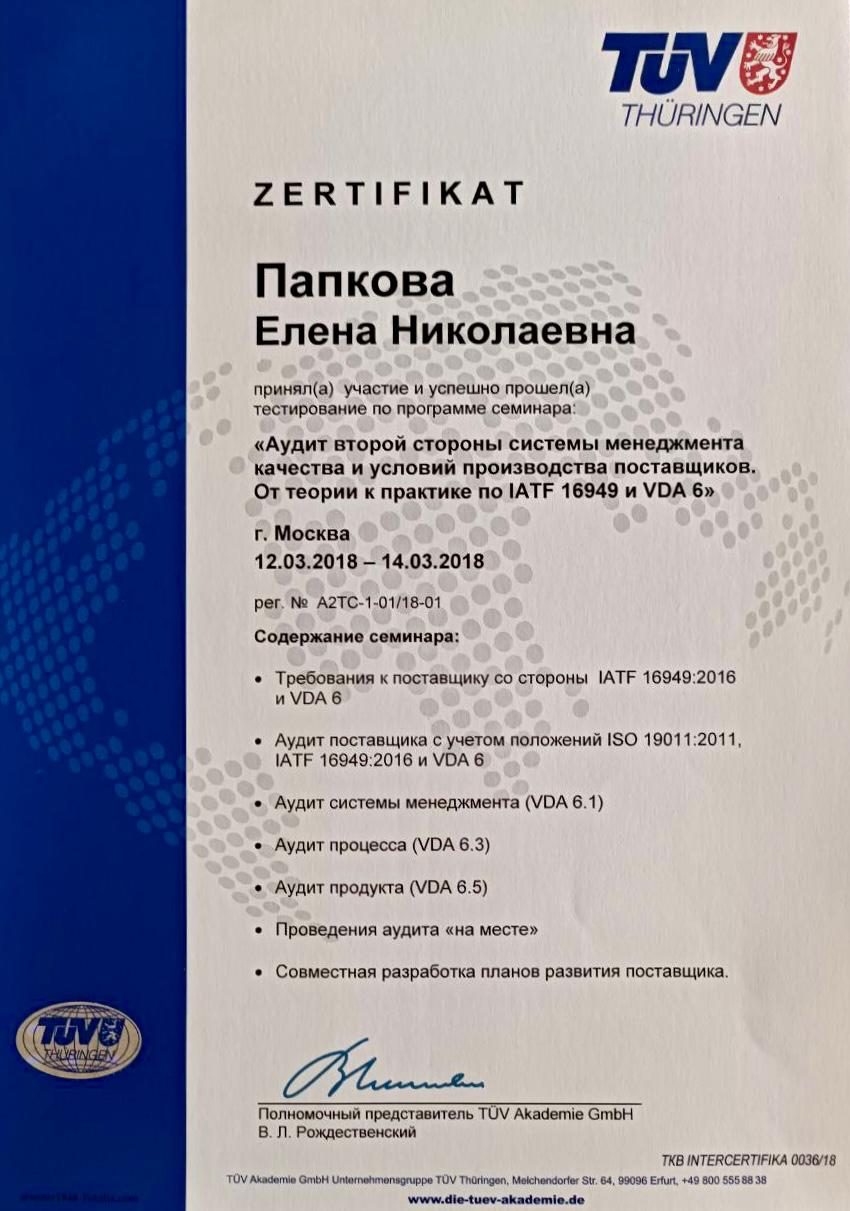

Elena Papkova

Quality expert, QMS implementation and maintenance

More than 40 years of experience in implementing QMS in various industries, including automotive industry, while working in large Russian and international companies “Khimvolokno”, “Elinar”, “AAT”.

Certified auditor according to ISO 9000 ; ISO 14000; IATF 16949 standards

Svetlana Matyunina

Finance Director

More than 20 years of experience in managing finance departments of large international corporations (including more than 10 years of experience in Tier1 OEM)

Setting up a system of planning, analysis, control and accounting from scratch, organization of the system of management of mutual settlements and making payments

Jeff Hao

PRC Supplier Audit

More than 10 years of experience in managing quality departments of large international corporations

Lean 6 Sigma level Black Belt level Lean 6 Sigma certification holder.

Why choose us

Project support at all stages 24/7

Liability for deliveries under Russian law

FLEXIBILITY IN FINDING SOLUTIONS, HIGH ADAPTABILITY TO THE RAPIDLY CHANGING EXTERNAL ENVIRONMENT

Time-proven coherence and competence of the team's experts, who have extensive experience in various fields of industry, including international holdings in the automotive industry.

Certificate of Compliance

The company has received ISO: 9001 certificate of conformity

All SCS production sites are audited for compliance with the customer requirements through a visit by a certified auditor. Based on the identified non-conformities, a master-plan is formed as a part of the supplier development procedure.

CONTACT US

Contact information

our social media

Our address

115230, г. Москва, Муниципальный округ Нагатино-Садовники,

Каширское шоссе, д. 13 Б .помещение 1/5

Contact Phone:

+7 977 302‑35‑00

E-mail:

info@smithcrafts.ru